Importance of Maintaining Clean Pipe Systems

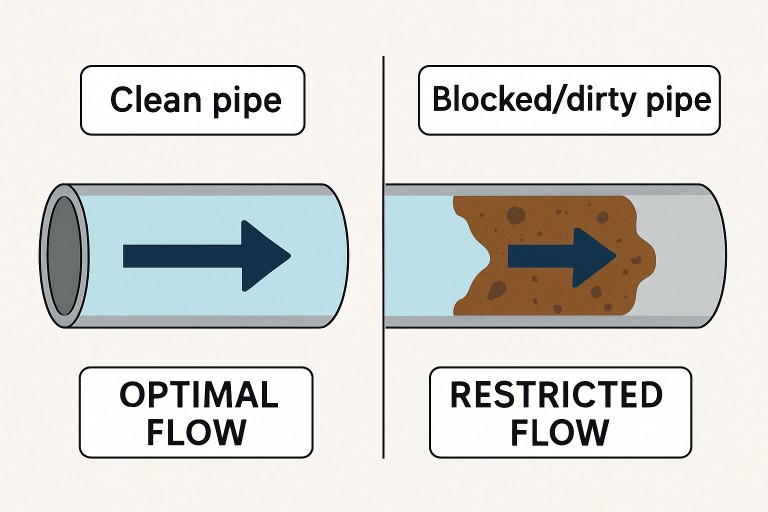

Clean pipe systems form the backbone of reliable industrial and municipal operations. Disruptions from accumulated debris cause unexpected downtime and often lead to higher costs through emergency repairs and productivity losses. Proactively maintaining clean pipe systems is a sound investment for any operation that relies heavily on fluid or material transport.

Partnering with proven suppliers such as Cruco Mill & Industrial Supply North Carolina ensures access to quality pipe maintenance products and expertise. Focusing on regular cleaning can mean the difference between seamless operations and costly system failures, as facilities that neglect routine care often experience persistent challenges, including frequent breakdowns and health concerns linked to contaminated flow.

Common Causes of Pipe Contamination

Understanding the sources of pipe contamination is vital for prevention. The most prevalent causes include:

- Mineral Deposits: Water with high mineral content can lead to scale buildup that reduces flow and efficiency.

- Biological Growth: Bacterial and algal growth significantly contribute to reduced pipe quality, particularly in slow or stagnant sections.

- Corrosion: When pipe material reacts chemically with transported media or environmental moisture, corrosion and subsequent pipe damage occur, further exacerbating contamination risks.

These issues are not limited to any single industry. Contamination in manufacturing, water treatment, or chemical processing can have far-reaching implications, from lost revenue to regulatory fines and even threats to personnel safety.

Many organizations overlook early warning signs of contamination until a minor issue escalates to a costly emergency. Addressing these root causes head-on is key to preventing system disruption and maintaining public health standards. For additional insights into pipe contamination problems, the EPA’s resource on water quality offers further details on microbial and mineral buildup.

Effective Strategies for Pipe Cleaning

Industry best practices advocate a combination of mechanical, chemical, and hydraulic methods to maintain clean pipe systems. Each has its unique advantages and applications:

- Mechanical Cleaning: Tools like pipe brushes and pipeline ‘pigs’ physically scrub internal surfaces to remove residues and deposits.

- Chemical Cleaning: Targeted chemical solutions dissolve stubborn contaminants, including mineral scale, biological films, and corroded material.

- Hydro Jetting: High-pressure water jets dislodge blockages and clean pipe interiors without leaving chemical residues.

The right choice depends on the specific type and degree of contamination and the nature of the pipe material. Many successful maintenance programs combine these approaches to maximize effectiveness, reduce downtime, and ensure compliance with industry standards.

Technological Advancements in Pipe Maintenance

Advances in pipe maintenance technology have made it possible to predict failures and schedule interventions with far greater accuracy. Machine learning algorithms, for instance, can analyze operational data to detect early signs of stress or contamination. Predictive maintenance tools not only help reduce human error but also extend the operational lifespan of critical infrastructure. Major cities and industrial complexes increasingly leverage such solutions to prevent failures and minimize service interruptions.

For example, a recent study found that integrating analytics and smart sensors can cut water main break rates by up to 40% thanks to early warnings and targeted interventions. For an in-depth exploration, the article “Indiana Steel Mill Reuses a Half Million Gallons of Water” outlines how digitalization transforms maintenance routines for public utilities and industry.

Case Studies of Successful Pipe Maintenance

Real-world results support the benefits of comprehensive pipe cleaning programs. At a large manufacturing plant, bi-annual hydro jetting led to a 30% reduction in unplanned downtime, directly translating to substantial repair costs and productivity savings. Water utilities employing predictive maintenance software have reported marked decreases in emergency service calls and extended pipe lifespans.

These case studies reinforce the value of integrated maintenance programs in terms of cost savings and improved health, safety, and customer satisfaction across sectors.

Cost-Benefit Analysis of Regular Pipe Cleaning

While routine pipe cleaning involves ongoing investment, the long-term savings are substantial. Preventive maintenance reduces operational downtime, preserves system integrity, and often helps meet or exceed regulatory compliance. The return on investment is clear compared to the expenses of emergency responses, line replacements, and lost production.

In fact, according to ASCE’s analysis of pipe infrastructure, every dollar spent on proactive maintenance can save as much as five dollars in emergency and replacement costs. Companies and municipalities that embrace regular pipe cleaning see dramatically improved operational efficiency and fewer service disruptions.

Best Practices for Implementing Pipe Cleaning Programs

- Conduct routine inspections leveraging manual checks and digital monitoring systems to catch early-stage issues.

- Customize maintenance schedules to match pipe materials, transported substances, and operational load.

- Incorporate a mix of cleaning approaches to address the most stubborn and varied contaminants.

- Provide ongoing training for maintenance staff, focusing on safety, innovative cleaning technologies, and regulatory compliance.

Consistency and documentation are key. Tracking performance metrics before and after maintenance helps justify costs and facilitates a culture of continuous improvement.

Conclusion

Preventing downtime through clean pipe systems is essential for long-term operational success. Industries can ensure infrastructure reliability and cost efficiency with a clear understanding of contamination sources, effective cleaning strategies, and modern predictive technologies. Facility managers and engineers looking for reliable support should consult experts to optimize and future-proof their pipe maintenance strategies.