Planning a new driveway or replacing an old, cracked surface can raise many questions for homeowners, and with the variety of materials and techniques available today, it’s no wonder many feel overwhelmed by the options. Making can lead to decades of worry-free use, increased curb appeal, and a solid return on your investment. From understanding the differences between materials to budgeting and even considering eco-friendly innovations, there’s more to driveway paving than meets the eye. Homeowners frequently turn to trusted services specializing in asphalt solutions for private roads when seeking a harmonious balance between cost, durability, and maintenance simplicity.

This comprehensive guide sheds light on every phase of the driveway journey—helping you navigate choices, avoid pitfalls, and benefit from up-to-date practices. Unlock insights drawn from field-tested experience and current research, giving you everything you need to make confident, informed decisions about your driveway project. Whether you’re resurfacing, starting from scratch, or looking to upgrade your current surface, you’ll find expert-backed answers and practical tips to shape the outcome for years to come.

Popular Driveway Paving Materials

Material selection lays the groundwork for how your driveway looks, performs, and stands against the elements. Asphalt is a front-runner for its relatively low installation cost, professional appearance, and flexibility to accommodate seasonal expansion and contraction. The distinctive blacktop finish is visually appealing and warms quickly in the sun, often helping to melt winter ice more rapidly in cold climates. Longevity is a key advantage—when maintained well, asphalt can last 15–20 years, with reports of even longer life in moderate climates. Discussions of recent industry trends in paving materials highlight asphalt’s persistent popularity, especially in regions with significant freeze-thaw cycles, where flexibility is necessary.

Concrete, however, works best for those prioritizing durability and design flexibility. The option to stamp, tint, or shape the surface allows for creative flair, while the inherent strength of concrete supports heavier vehicles and resists rutting. However, climate matters too—concrete can be prone to cracking in areas where the ground shifts dramatically with the seasons, making professional installation and site-specific techniques crucial.

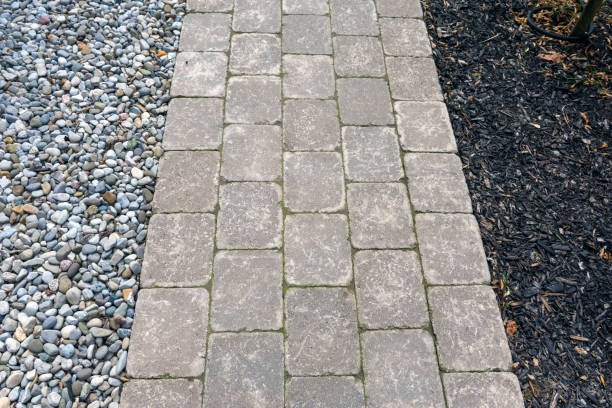

Gravel driveways provide a budget-friendly solution and are valued for their ability to handle drainage naturally. Their rustic charm suits rural homes, though frequent raking and periodic top-ups are required to keep the surface smooth and prevent spreading. If appearance and repair ease are top priorities, paver or brick driveways deliver on both, with the bonus that individual sections are simple to swap out if damaged.

- Asphalt: Smooth, efficient, handles climate extremes, is fast to install, and has a low upfront cost.

- Concrete: Highly durable, numerous design options, long lifespan, more expensive than asphalt.

- Gravel: Excellent drainage, quick installation, minimal upfront investment, higher maintenance.

- Pavers/Bricks: High visual impact, modular repair, greater initial cost.

The decision revolves around climate, daily use, personal taste, and willingness to stay on top of ongoing care. Choosing wisely at this stage will influence everything from your future maintenance schedule to your property’s resale appeal.

The Preparation Process Demystified

What happens before paving gets underway is just as vital as the actual materials chosen. A project that skips steps in base preparation is prone to settling, cracking, and drainage headaches. First, the site is evaluated for drainage patterns and stability. Old materials are stripped away, after which the ground is graded and leveled to promote water runoff away from the home and critical structures. The proper slope prevents flooding, pooling, or long-term erosion.

Next comes the installation of a solid subbase—usually several layers of crushed rock compacted to form a firm, even cushion. This base is key to avoiding dips and depressions that develop after heavy use. Good contractors know to pay special attention to soil type and moisture, adjusting clay, sand, or silt to provide a solid foundation tailored to local conditions.

Weather plays a decisive role in scheduling: Paving is always best completed in fair weather that allows proper setting or curing. While it may be tempting to rush the process, investing sufficient time in this preparatory phase yields a smoother surface that resists cracking and settling, boosting both appearance and lifespan.

Maintenance Tips for Lasting Results

Driveways that are exposed to the elements benefit from regular attention. For asphalt, sealing every three to five years prevents water, oil, and chemicals from seeping into small cracks and breaking down the structure underneath. The deep black finish also resists UV damage and can be refreshed with each new coat. Concrete surfaces, although tougher in some respects, should have cracks filled as soon as they appear and be kept clean of stains to avoid permanent marks.

Routine Maintenance Checklist:

- Sweep and frequently remove organic debris (leaves, sticks) to prevent surface breakdown.

- Inspect for cracks or holes after winter and heavy storms—patch minor issues before they expand.

- Gravel driveways must be raked periodically; top up lost stone to maintain depth and performance.

- Use de-icers sparingly on concrete and asphalt to protect against accelerated wear and surface pitting.

After major storms or rapid seasonal changes, inspect your driveway for tell-tale signs of wear. Early action, such as filling cracks or patching washed-out sections, can nearly double the functional lifespan of the surface and avoid costlier repairs down the road.

Common Myths About Driveway Paving

Separating fact from fiction can prevent disappointment and wasted resources. A common myth is that asphalt driveways will inevitably degrade after just a few winters—this isn’t true when routine sealing and repair are done. Similarly, believing that concrete needs no maintenance leads many experts to overlook the importance of cleaning and crack repairs, which help it achieve a projected decades-long lifespan.

Another bit of misinformation is that all driveways can be built similarly, regardless of what’s underneath. In reality, locals dictate everything from base thickness to drainage design. Many handy guides from trusted home improvement resources urge property owners to do their homework or consult experienced professionals to ensure their driveway foundation is up to par.

Ultimately, understanding the facts about installation and care makes it easier to avoid shortcuts that seem cheaper now but often result in significant repair bills later.

What Drives Paving Costs?

Budgeting for a driveway involves more than picking a material and calculating square footage. Labor, geographic location, and the condition of your existing site affect the final bill. For instance, removing expansive tree roots or addressing the slope can add significant cost. Regional differences in material and labor pricing can have a considerable impact—an asphalt driveway in the Midwest may be thousands cheaper than a similar one in a coastal city.

What Impacts Cost?

- The overall size, length, driveway’s thickness, driveway shape, and intricate patterns cost more.

- ThickThicknesshe paving material (thicker is usually better, but more expensive).

- The amount and complexity of site prep—removing trouble spots adds time and labor.

- Local labor rates and material availability.

- Upgrades such as integrated lighting, decorative borders, or specialized drainage.

If you need to stretch your dollars, phasing the project (completing the essentials first, adding extras over time) is smart. While it’s tempting to shave or base layer, investing here will save far more when repairs or replacement are needed.

Eco-Friendly Options and Innovations

Today, sustainability often drives home improvement projects. Homeowners can now choose materials like permeable concrete and pavers that let rainwater drain naturally, reducing stormwater runoff and minimizing the heat island effect. Recycled asphalt and concrete—using materials salvaged from old surfaces—minimize environmental impact by lowering resource extraction.

Some communities even offer incentives for green driveways, supporting eco-friendly paving solutions. New technologies can include subsurface structures designed to recharge groundwater and surface coatings that reflect solar heat and keep outdoor spaces cooler. Combining these options preserves function while supporting the health of your landscape and the greater environment.

Expert Insights and Advice

Professionals in the field consistently recommend a thorough site assessment and a detailed conversation before any paving starts. Ask about the projected lifespan of different materials, whether the bid includes grading for drainage, and what kind of guarantee the work carries. Push for a written, itemized contract, and don’t hesitate to review references or look up reviews from previous customers.

- Discuss site-specific concerns such as tree roots, slope, or proximity to water lines before work begins.

- Ensure the contractor is licensed, insured, and familiar with local codes.

- Confirm that the timeline accounts for weather delays and that maintenance instructions are explained after installation.

The best way to safeguard your new investment is to keep the conversation open with your contractor and get clear, documented commitments.