CNC turning is crucial for obtaining precise and intricate parts of high quality within the aerospace, automotive, medical and industrial equipment sectors. As precision parts become highly specialized, there is an increasing requirement for skilled and reliable precision parts factory partners.

This is the first installment of a comprehensive series focused on the perspective of an engineer that deals with internal and external components of CNC turning machines. We’ll go through the processes involved in creation, material selection, probable applications, branding concerns and benefits of working with reputable CNC turning parts suppliers. These insights will help you whether you are managing prototypes or supervising mass production, and equip you for better choices.

Understanding CNC Turning and Its Role in Part Production

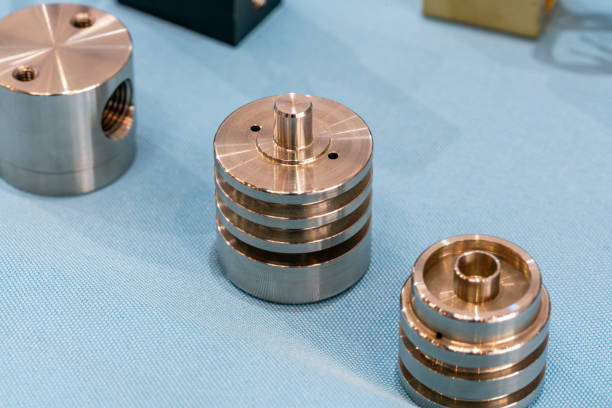

CNC turning is a process that works by material removal via a rotating tool and a fixed cutting tool. It is done wholly or partially for cylindrical, symmetrical components such as shafts and pins, and is very efficient for such geometries. CNC turning becomes handy for fast-paced industries due to its ability to create components that have high precision, which is very crucial during micron level operations.

Factories operating at an industrial level with advanced automated features such as multi axed CNC turning capable of live tool operation, tend to experience great improvements in speed, accuracy, and efficiency with reduced cycle times and manual error. Meeting the demands for producing high volumes of identical products becomes easier with the added ability to automate quality checks.

CNC turning is not limited to conventional materials such as aluminum and stainless steel, but also extends to titanium, brass, and even exotic polymers. Components being produced have to meet certain criteria in functional and material properties and for applications in high performance environments, CNC turning makes sure those needs are satisfied.

Key Considerations in Material and Design Selection

The first step in CNC turning really begins with deciding on material and design parameters. Everything from strength, machinability, corrosion resistance, and thermal conductivity are of utmost importance to performance and production costs.

In the design phase, precision parts factory teams closely collaborate with clients to suggest optimal materials and tolerances. This early involvement guarantees the design can be manufactured as intended. For instance, minimizing the number of setups or tool changes often leads to cost efficiency while maintaining quality. The materials are chosen depending on the application be it lightweight structures, high strength mechanical components, or even corrosion resistant parts to make sure the appropriate choice for durability and reliability is made.

Optimization of stress points, weight, and geometry for CNC turning also falls under design. Clients working with experienced CNC turning parts manufacturers usually have several CAD models which require minimal adjustment and a lot of machining, enabling manufacturers to operate in a reduced lead time scenario. These partnerships almost guarantee success in highly competitive industries where product life cycles are extremely short and quick to market is prioritized.

Why Partnering with a Precision Parts Factory Matters

A precise parts manufacturing company is not only an asset for the location of the machines but also brings experience, machinery assistance, and quality control. These partners help in sourcing of materials and aid in the prototyping, mass production as well as post production which helps simplify the supply chain.

Factories that do CNC turning possess high-end measuring equipment such as CMMs and optical inspection systems. These capabilities guarantee that all the parts are manufactured within the strict predetermined tolerances which is a great relief to engineers and buyers. It is extremely important to manage the quality before the final product is assembled in order to avoid further complications like fitting the piece into its final application, dealing with the dimensional deviation and fulfilling the perfect performance or failed components.

The ability to scale production without loss of quality provides competitive advantage to any firm. Companies that seek to validate their ideas can easily get 100 pieces while those seeking to deploy mass production can get 100,000 parts. The speed at which these companies are able to meet the demand without upsetting their processes is greatly valued. This is especially true for applications where the end result is life critical, such as medical devices and components for aerospace engineering. The right manufacturing partner enables businesses to manage risk with production in full swing, guaranteeing quality, and timeliness.

CNC Turning Parts Manufacturers and the Challenges They Overcome

Even with modern technology, CNC turning brings its own challenges such as tool wear, material inconsistencies, and thermal expansion which can negatively impact tolerances. This is where expert CNC turning parts manufacturers come into play. They understand that controlling spindle speeds, feed rates, and coolant application mitigate risks of inconsistencies, especially when machining hard-to-machine materials like titanium or high carbon steels.

Another challenge is surface finish. Some applications such as optical mounts or fluid handling systems require design surfaces with high degrees of smoothness. Precision manufacturers are aware of how to use correct insert geometries, along with finishing passes and secondary treatments such as polishing and coating, to address these rigorous demands. Meeting these challenges enables the manufactured parts to be functional, durable and suitable for the intended use.

Another issue that has to be solved is programming. Sophisticated CAM software is used for simulating operations, optimizing toolpaths, and avoiding their collisions before even a single part gets on the lathe. For B2B customers that have to deal with complex supply chains, this ensures a smooth production process. The ongoing development of automation and software tools greatly contributes to obtaining lower cycle times and increased cost efficiency.

Conclusion

For engineers working in high-stakes, high-volume industries, understanding CNC turning is essential. From design principles to material selection and quality control, CNC turning offers unmatched precision and efficiency when managed by a skilled precision parts factory. With continuous advancements in CNC turning technology, it’s crucial to stay informed about emerging trends that will continue to shape the future of manufacturing.

Choosing the right partner—one of the top CNC turning parts manufacturers—can make the difference between smooth production and costly setbacks. With the right collaboration, businesses can bring innovative products to market faster, ensure dimensional accuracy, and maintain a strong competitive edge in demanding markets. Whether you’re a product developer, engineer, or procurement manager, a deep knowledge of CNC turning is not just beneficial—it’s strategic.